Description

Chemical Identity

-

Chemical Name: 2-Hydroxypropyl Methacrylate

-

Abbreviation: HPMA

-

Chemical Formula: C7H12O3

-

Molecular Weight: 144.17 g/mol

-

CAS Number: 27813-02-1

-

EC Number: 248-666-3

Specifications of 2-Hydroxypropyl Methacrylate

| Property | Specification |

|---|---|

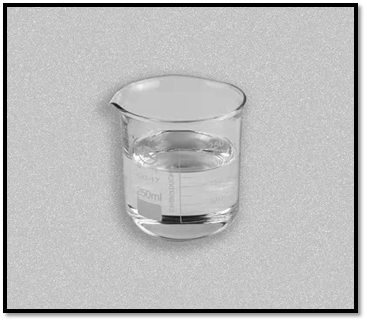

| Appearance | Clear, colorless liquid |

| Purity | ≥ 96% |

| Boiling Point | ~100–102°C at 5 mmHg |

| Density (20°C) | 1.03 g/cm³ |

| Viscosity (25°C) | 20–30 mPa·s |

| Flash Point (Closed Cup) | 99°C |

| Refractive Index (n20/D) | 1.451 – 1.454 |

| Solubility | Miscible with water and most organic solvents |

| Stabilizer Content | Typically contains MEHQ (monomethyl ether hydroquinone) as inhibitor |

Applications of HPMA

🔬 Coatings and Surface Finishes

HPMA is widely used in industrial coatings, protective topcoats, and UV-curable paints. Its hydroxyl group allows for crosslinking with isocyanates or melamine resins, improving durability, scratch resistance, and chemical stability.

🖨️ Printing Inks and Adhesives

As a functional monomer, HPMA enhances adhesion to various substrates and boosts flexibility and resistance to yellowing in inks and pressure-sensitive adhesives.

🧴 Medical and Personal Care Polymers

HPMA is also utilized in the development of biocompatible hydrogels, dental materials, and drug delivery systems due to its ability to form hydrophilic, crosslinked structures.

🏭 Acrylic Resins and Elastomers

It plays a critical role in emulsion polymerization, producing flexible, impact-resistant acrylic resins used in automotive parts, plastic coatings, and construction materials.

Handling and Safety

-

Hazards: HPMA is classified as an irritant and may cause skin or eye irritation.

-

Personal Protective Equipment (PPE): Use gloves, goggles, and protective clothing.

-

Storage Conditions: Store in a cool, dry place away from sunlight and ignition sources. Keep container tightly closed and protected from oxygen to prevent premature polymerization.

Conclusion

2-Hydroxypropyl Methacrylate (HPMA) is a versatile monomer with a broad spectrum of industrial applications, thanks to its unique chemical properties. Its ability to improve adhesion, flexibility, and chemical resistance makes it indispensable in coatings, adhesives, inks, and medical-grade polymers. With high purity and excellent reactivity, HPMA remains a preferred material for formulators seeking durable, high-performance, and customizable polymer solutions.

![Glutaraldehyde 50% Industrial Grade [With or Without formaldehyde available]](https://mjrdchemhome.com/wp-content/uploads/2025/04/camachem_-_glutaraldehyde_50_2_-300x300.jpg)