Description

🔍 Technical Specifications of Chloroprene Rubber CR2322

| Property | Specification |

|---|---|

| Chemical Structure | Poly(chloroprene), non-sulfur modified |

| Form | Light yellow or pale brown rubber chips |

| Mooney Viscosity (ML 1+4 @100°C) | 35–45 |

| Crystallization Rate | Medium |

| Tensile Strength | ≥ 20 MPa (depending on compound) |

| Elongation at Break | ≥ 600% |

| Density (Specific Gravity) | ~1.23 g/cm³ |

| Ash Content | ≤ 0.7% |

| Volatile Matter | ≤ 1.0% |

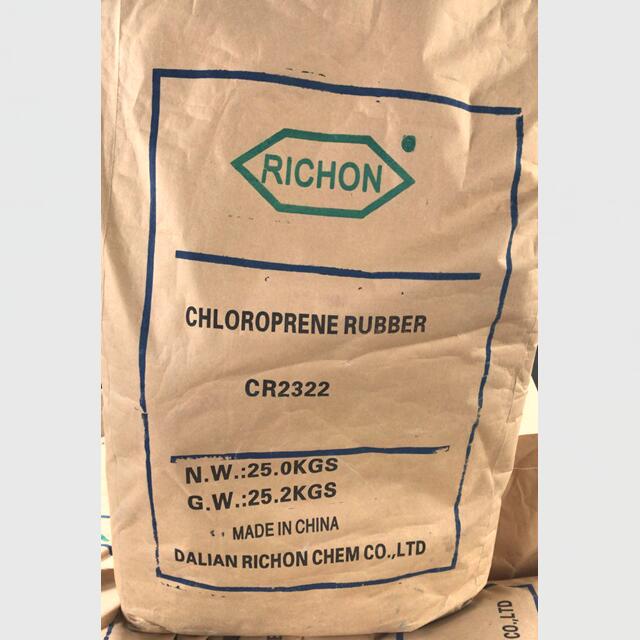

| Packaging | 25 kg PE-lined moisture-proof bags |

| Shelf Life | 1 year in cool, dry conditions |

💡 Applications of CR2322 Chloroprene Rubber

1. Automotive Industry

CR2322 is commonly used in automotive hoses, gaskets, seals, and vibration dampers, where a combination of flexibility, oil resistance, and aging durability is needed.

2. Adhesives and Sealants

This rubber grade offers strong bonding compatibility with various tackifiers and resins, making it useful in solvent-based adhesive applications such as shoe adhesives, industrial glues, and contact cements.

3. General Rubber Goods

Its ease of processing makes CR2322 suitable for extrusion, compression molding, and injection molding applications, including rubber sheets, sealing strips, foam materials, and coated fabrics.

✅ Key Benefits of Chloroprene Rubber CR2322

-

✔️ Excellent processability – Ideal for extrusion and molding

-

✔️ Medium crystallization rate – Balanced bonding and strength

-

✔️ Good resistance to oil, ozone, and UV exposure

-

✔️ Versatile compatibility with a wide range of additives and resins

-

✔️ Reliable mechanical properties for general-purpose use

⚠️ Storage & Handling

-

Store in a cool, dry environment away from direct sunlight.

-

Use standard safety equipment when processing or blending.

-

Avoid contact with oxidizing agents and excessive heat.

📌 Conclusion

Chloroprene Rubber CR2322 is a highly versatile, general-purpose neoprene rubber ideal for a wide range of industrial applications. With its medium crystallization speed, excellent aging resistance, and outstanding processability, it strikes the right balance between performance and flexibility. Whether used in automotive seals, adhesives, or molded rubber parts, CR2322 remains a dependable material that delivers consistent results in demanding environments.