Description

What is a Flocculant?

A flocculant is a chemical substance—usually a polymer—that facilitates the process of flocculation, where fine particles clump together into larger aggregates (flocs). These flocs can then be separated from the liquid through settling, filtration, or flotation.

Flocculants can be classified based on their ionic charge:

-

Anionic flocculants (negatively charged): Ideal for suspensions with positively charged particles like metal oxides.

-

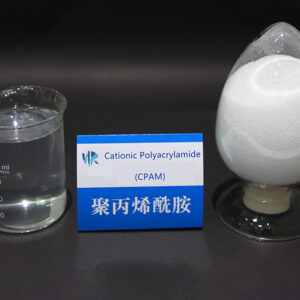

Cationic flocculants (positively charged): Effective for organic sludge and negatively charged particles like clay.

-

Nonionic flocculants (neutral): Suitable for systems with low ionic strength or where ionic interaction is minimal.

General Specifications of Flocculants

| Property | Typical Range |

|---|---|

| Physical Form | Powder, granular, or emulsion |

| Molecular Weight | 5 to 25 million Dalton (varies by type) |

| Ionic Charge Type | Anionic, Cationic, Nonionic |

| Charge Density | 5% to 80% (depending on formulation) |

| Solubility in Water | Fully soluble |

| Recommended pH Range | 4 – 10 (varies by application) |

| Shelf Life | 1 to 2 years (cool, dry storage) |

Applications of Flocculants

1. Municipal and Industrial Wastewater Treatment

Flocculants are crucial in the clarification and purification of wastewater, helping to remove suspended solids, organic matter, and turbidity. They are used in both primary and secondary treatment stages, often in combination with coagulants.

2. Drinking Water Treatment

In potable water systems, flocculants assist in removing fine particulates and natural organic matter, making water safe and clear for consumption.

3. Mining and Mineral Processing

Used extensively in ore beneficiation and tailings management, flocculants promote the rapid sedimentation of mineral slurries and recovery of process water.

4. Papermaking Industry

Flocculants help in the retention of fillers and fines, improving paper strength and reducing water loss during the sheet formation process.

5. Oil and Gas Industry

In drilling and refining operations, flocculants enhance sludge dewatering and waste stream treatment, improving operational efficiency.

Benefits of Using Flocculants

✅ Improved solid-liquid separation

✅ Faster settling and clarification

✅ Reduced chemical oxygen demand (COD) and turbidity

✅ Enhanced sludge dewatering

✅ Lower dosage requirements compared to traditional coagulants

✅ Cost-effective and environmentally friendly when used correctly

Their versatility and efficiency make flocculants indispensable across many sectors focused on sustainable water and waste management.

Safety and Handling

While flocculants are non-toxic in diluted form, they should be handled carefully in their concentrated state. Avoid skin and eye contact, wear personal protective equipment, and store the product in a cool, dry, and well-ventilated area. Always refer to the Material Safety Data Sheet (MSDS) for safe handling practices.

Final Thoughts

Flocculants are foundational to modern water treatment and industrial processes, offering a simple yet powerful solution for improving clarity, efficiency, and environmental compliance. Their ability to adapt to different water chemistries and treatment goals makes them a critical tool for industries seeking cleaner operations and lower costs.

Whether you manage a municipal water plant, operate a mining facility, or run an industrial treatment system, choosing the right flocculant can significantly improve your outcomes and support your sustainability goals.

![ferric aluminum sulfate flake 16% [furrous]](https://mjrdchemhome.com/wp-content/uploads/2025/04/camachem_-_ferric_aluminium_sulfate_flakes_2_-300x300.jpg)