Description

🔬 Specifications of Formic Acid 99%

-

Chemical Name: Formic Acid

-

Chemical Formula: CH₂O₂

-

CAS Number: 64-18-6

-

Molecular Weight: 46.03 g/mol

-

Purity: ≥ 99%

-

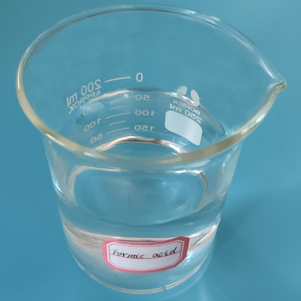

Appearance: Colorless, transparent liquid

-

Density: 1.22 g/cm³

-

Boiling Point: 100.8°C (213.4°F)

-

Freezing Point: -8.4°C (16.9°F)

-

Solubility: Completely miscible in water, ethanol, ether

-

Acidity (pH): Strongly acidic, pH 2–3 in aqueous solutions

-

Storage Conditions: Store in a cool, dry place away from direct sunlight and incompatible materials

-

Packaging: Available in 25 kg, 50 kg, or bulk containers

-

Shelf Life: 12–24 months when stored properly

🔧 Applications of Formic Acid 99%

1. Agriculture and Animal Feed

Formic acid 99% is commonly used in the agriculture industry, primarily as a preservative for silage and feed. It helps in preserving the nutritional quality of animal feed by controlling the growth of harmful microorganisms, thus preventing spoilage and ensuring livestock health. Additionally, it acts as a feed additive, providing benefits such as improving digestion and enhancing the absorption of nutrients in animals.

2. Chemical Synthesis

Formic acid is an important reagent in the chemical industry, where it is used to produce a wide range of compounds such as formate esters, plasticizers, and pharmaceuticals. It plays a critical role in reducing agents in various organic reactions, such as in the synthesis of polymers and rubber. It is also used in the production of methyl formate and formamide, essential intermediates in industrial processes.

3. Textile Industry

In the textile industry, formic acid 99% is used as a dyeing agent, particularly for wool and silk. Its acidic nature helps in fixing dyes and improving the quality and durability of fabrics. It also acts as a pH regulator in the bleaching and finishing processes of textiles.

4. Leather Industry

Formic acid plays an essential role in the tanning of leather. It is used to lower the pH of tanning solutions, ensuring the proper formation of tanning agents that help preserve the leather and maintain its flexibility. It is also utilized to clean leather and improve the final product’s texture and durability.

5. Food Preservation and Additive

Formic acid 99% is used in food preservation, especially in pickling and preserving meat products. It helps prevent the growth of bacteria and other pathogens, extending the shelf life of foods. Additionally, it is used as a food additive under the code E236 to regulate the pH in certain processed foods.

✅ Benefits of Formic Acid 99%

-

✔️ High acidity for effective preservation and microbial control

-

✔️ Versatile uses across industries such as agriculture, textiles, and chemicals

-

✔️ Improves feed quality and digestion in livestock

-

✔️ Enhances leather tanning and textile dyeing

-

✔️ Environmentally friendly compared to other preservatives and chemicals

-

✔️ Soluble in water, making it easy to incorporate into various formulations

⚠️ Safety and Handling

Formic acid 99% is a corrosive and hazardous substance, and its handling requires precautionary measures to ensure safety. Direct contact with skin or eyes can cause severe burns, and inhaling vapors may lead to respiratory irritation. It is critical to wear protective gloves, goggles, and a respirator when handling the substance. Proper ventilation is required to prevent the accumulation of vapors in the work environment. Formic acid should be stored in tightly sealed containers in a cool, dry place, away from oxidizing agents and strong bases to avoid dangerous reactions. Always refer to the Material Safety Data Sheet (MSDS) for detailed safety instructions.

📌 Conclusion

Formic Acid 99% is a powerful and versatile chemical with numerous applications across agriculture, chemical synthesis, textile manufacturing, leather processing, and food preservation. Its high acidity and broad reactivity make it an invaluable compound in various industries. Whether it is used as a preservative in animal feed, a reagent in chemical production, or a tanning agent in leather processing, formic acid contributes to improving product quality and extending shelf life. However, due to its corrosive nature, it is essential to handle it with care and follow safety guidelines to avoid harm.