Description

Technical Specifications of R-248 Titanium Dioxide

| Property | Specification |

|---|---|

| Chemical Name | Titanium Dioxide (TiO₂) – Rutile Form |

| Grade | R-248 |

| Manufacturing Process | Sulfate |

| TiO₂ Content | ≥ 94% |

| Crystal Structure | Rutile |

| Appearance | White, fine powder |

| Surface Treatment | Inorganic (Alumina) + Organic coating |

| Specific Gravity | ~4.1 |

| Oil Absorption | ≤ 20 g/100g |

| Refractive Index | ~2.76 |

| Volatile Matter | ≤ 0.5% |

| Dispersion in Polymers | Excellent |

| Weatherability | High |

Key Features and Advantages

1. Superior Opacity and Whiteness

R-248 delivers high hiding power and brightness, ensuring optimal color coverage and vibrant appearance in plastics. This reduces the amount of pigment required while maintaining color consistency.

2. Excellent Dispersibility

Thanks to its alumina surface treatment and controlled particle size, R-248 disperses easily in polymers such as PE, PP, PS, ABS, and PVC, minimizing agglomeration and enhancing production efficiency.

3. UV and Heat Stability

R-248 is engineered for thermal and UV resistance, making it suitable for both indoor and outdoor plastic applications. It helps prevent yellowing and degradation when plastics are exposed to sunlight or processing temperatures.

4. Low Oil Absorption

The low oil absorption rate of R-248 allows for better processing flow, making it ideal for high-speed extrusion, injection molding, and film blowing applications.

Typical Applications in the Plastic Industry

-

Plastic Masterbatches

Ensures high color strength and excellent dispersion in concentrate pellets. -

Thermoplastic Compounds

Used in PE, PP, PS, and other polymers to improve opacity and UV resistance. -

PVC Pipes and Profiles

Enhances durability, surface smoothness, and long-term performance in rigid PVC products. -

Plastic Films and Sheets

Provides high brightness and thermal stability for packaging and agricultural films. -

Engineering Plastics and Automotive Components

Offers excellent weatherability for functional and aesthetic plastic parts.

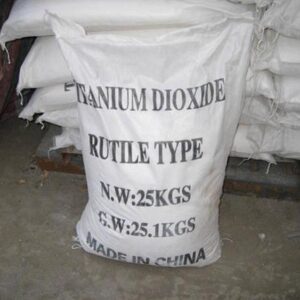

Packaging and Storage

R-248 titanium dioxide is typically available in 25 kg multi-layer bags, 500 kg jumbo bags, or customized packaging. It should be stored in a cool, dry place, protected from direct sunlight and moisture to maintain performance integrity.

Conclusion

Rutile Titanium Dioxide (Sulfate R-248 Grade) is a high-quality white pigment specifically tailored for the plastic industry. Offering superior opacity, thermal stability, UV resistance, and easy processing, it enhances both the performance and aesthetics of plastic products across a range of applications. Whether you’re producing masterbatches, films, or automotive components, R-248 ensures durability, brightness, and efficiency in every product.