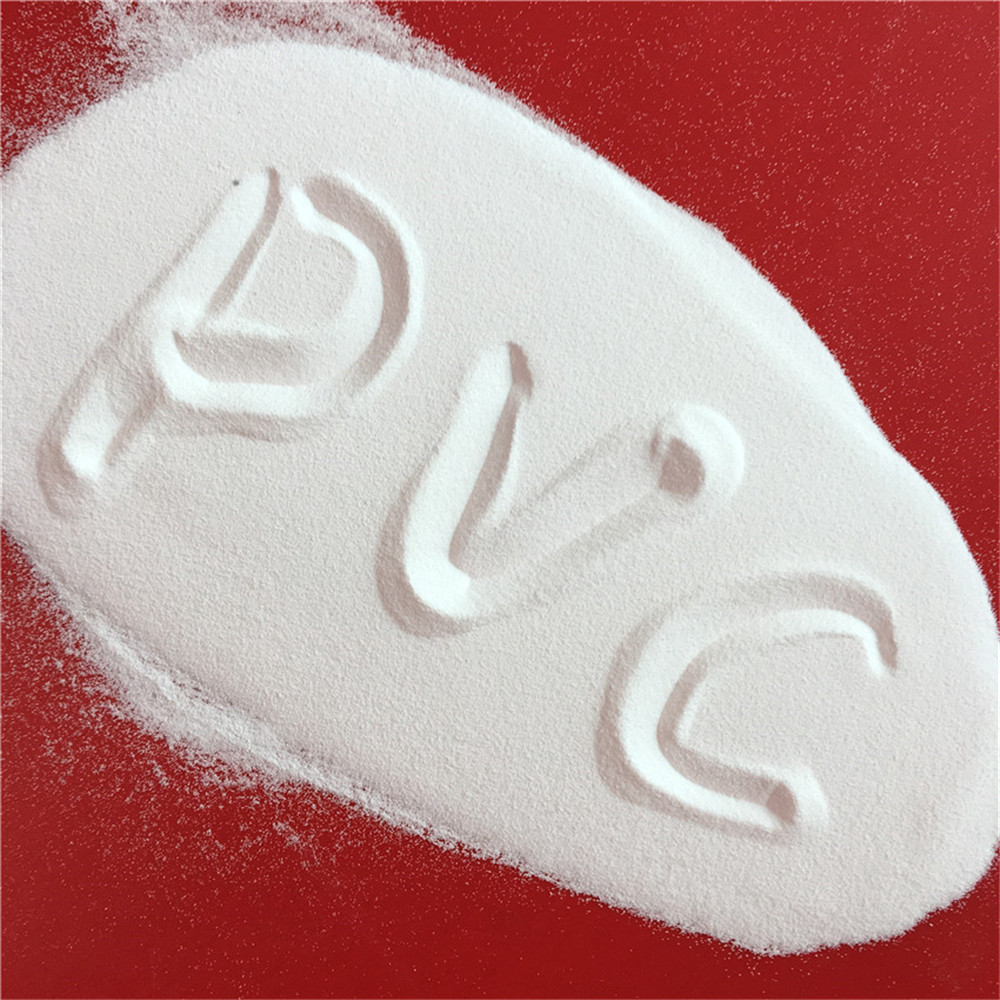

Description

Technical Specifications of PVC SG5 (PVC1091)

| Property | Typical Value / Range |

|---|---|

| Product Name | Polyvinyl Chloride SG5 (PVC1091) |

| Grade | Suspension Grade |

| K-Value | 66 – 68 |

| Viscosity Number (ml/g) | 107 – 118 |

| Apparent Bulk Density (g/cm³) | 0.48 – 0.60 |

| Volatile Content (%) | ≤ 0.40 |

| Particle Size (200 mesh) | ≥ 98% passing |

| Whiteness (160°C, 10 mins) | ≥ 80% |

| Fish Eye Count (per 400 cm²) | ≤ 20 |

| Impurity Particles | ≤ 16 |

| Moisture Content (%) | ≤ 0.3 |

| Plasticizer Absorption (DOP) | ≥ 18% |

Key Features and Advantages of PVC SG5

✅ Versatile Processing Capability

PVC SG5 can be processed using a variety of methods including extrusion, injection molding, blow molding, and calendaring. This makes it suitable for a wide range of products with varying shapes and properties.

✅ Excellent Mechanical and Thermal Stability

PVC SG5 offers strong tensile strength, impact resistance, and dimensional stability, along with consistent performance at elevated temperatures, which is essential for industrial and construction-grade products.

✅ Good Electrical Insulation and Chemical Resistance

This resin is non-conductive and resists damage from acids, alkalis, oils, and salts, making it ideal for electrical cable sheathing and chemical storage containers.

Applications of PVC SG5 (PVC1091)

-

Rigid and Semi-Rigid Pipes

Commonly used in water supply, drainage systems, and industrial piping. -

Profiles and Window Frames

Offers strong UV and weather resistance, perfect for building and construction applications. -

Film and Sheet Production

Used in packaging, protective sheets, and industrial liners. -

Injection Molded Products

Ideal for household goods, toys, tool handles, and automotive parts. -

Cable and Wire Insulation

Owing to its electrical insulating properties and durability under stress.

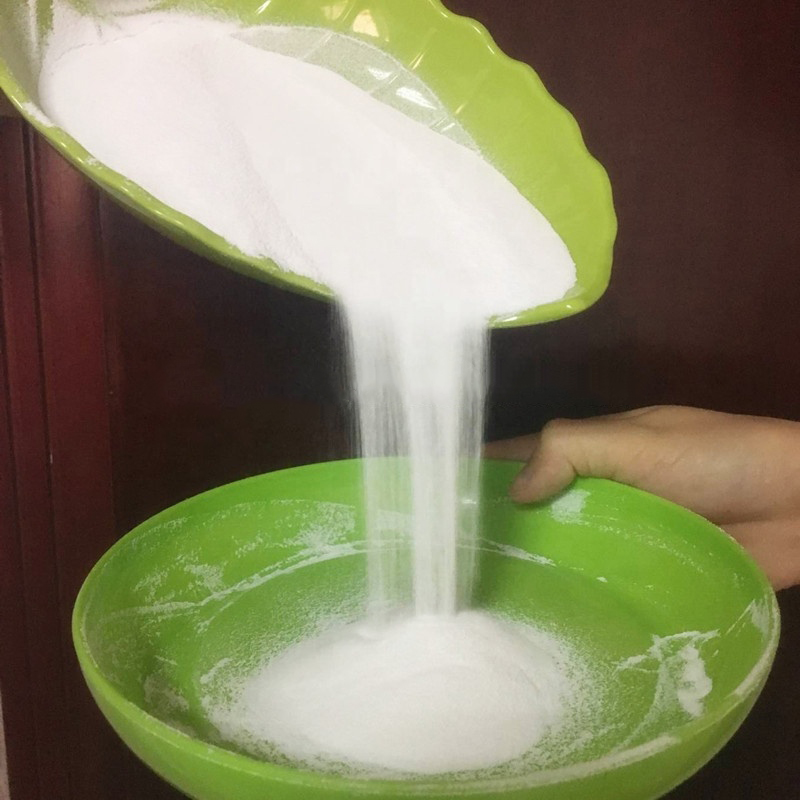

Packaging and Storage

PVC SG5 is typically packed in 25 kg woven bags with inner plastic liners or jumbo bags. It should be stored in a cool, dry, and well-ventilated area, away from heat sources and direct sunlight to prevent degradation or contamination.

Conclusion

Standard Polyvinyl Chloride (PVC SG5 or PVC1091) stands as a reliable, cost-effective, and high-performance thermoplastic resin suitable for a broad spectrum of applications. With its balanced molecular weight, low volatility, and excellent processability, PVC SG5 meets the needs of manufacturers in construction, packaging, electrical, and consumer goods industries. If you’re looking for a durable, easy-to-process, and economically viable PVC resin, SG5 is the industry standard.