Description

Technical Specifications of CR-350 Titanium Dioxide

| Property | Specification |

|---|---|

| Chemical Name | Titanium Dioxide (TiO₂) – Rutile Pigment |

| Grade | CR-350 |

| Production Process | Chloride Process |

| Crystal Form | Rutile |

| TiO₂ Content | ≥ 96% |

| Surface Treatment | Alumina and organic coating |

| Oil Absorption | ≤ 18 g/100g |

| pH Value (aqueous slurry) | 6.5 – 8.5 |

| Specific Gravity | ~4.1 |

| Refractive Index | ~2.76 |

| Whiteness / Brightness | High |

| Dispersion in Polymers | Excellent |

| Weatherability | Outstanding (suitable for outdoor use) |

Key Features and Advantages

1. High Whiteness and Opacity

CR-350 offers excellent hiding power and brightness, making it ideal for use in white and colored plastic formulations. It ensures clean, vivid shades with minimal pigment loading.

2. Excellent Dispersibility in Polymers

Due to its advanced surface treatment, CR-350 disperses uniformly in a wide range of plastic resins, including PE, PP, PVC, ABS, and engineering plastics. This leads to smooth, defect-free surfaces and consistent product quality.

3. Superior UV and Thermal Stability

The rutile structure and high purity of the pigment provide strong resistance to UV radiation and heat, ensuring long-lasting color performance in outdoor plastic products like garden furniture, siding, and pipes.

4. Low Volatility and Low Oil Absorption

Its low oil absorption improves melt flow properties, while its chemical stability under processing temperatures ensures optimal production efficiency and minimal impact on resin behavior.

Applications in the Plastics Industry

-

Masterbatches & Concentrates

CR-350 is perfect for white and colored masterbatches, offering excellent tinting strength and durability. -

PVC Products

Ideal for both rigid and flexible PVC, including profiles, window frames, pipes, and sheets. -

Polyolefin & Styrenic Plastics

Used in PP, PE, PS, and ABS resins for improved brightness and surface appearance. -

Engineering Thermoplastics

Enhances the aesthetic and functional properties of high-performance polymers used in automotive and industrial components. -

Plastic Films & Packaging

Delivers excellent opacity and light-scattering for multilayer films and barrier packaging.

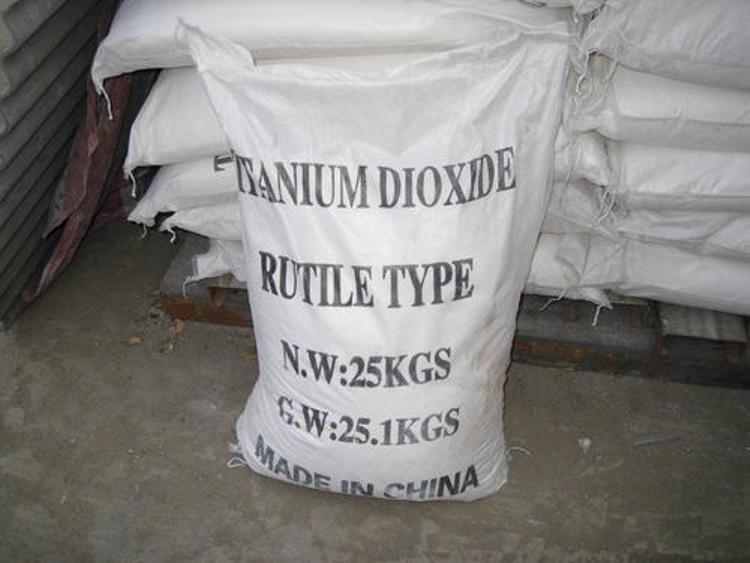

Packaging and Storage

CR-350 is commonly supplied in 25 kg paper bags, jumbo bags, or customized packaging upon request. For best results, store in a dry, ventilated area away from moisture and extreme temperatures.

Conclusion

Titanium Oxide Rutile Pigment CR-350, produced via the chloride process, is a top-tier white pigment for the plastics industry, offering unmatched opacity, UV resistance, dispersion, and whiteness. Its high-performance characteristics make it the pigment of choice for manufacturers seeking durability, processability, and aesthetic excellence in plastic products. Whether you’re formulating masterbatches, engineering resins, or flexible films, CR-350 ensures consistency and performance every time.